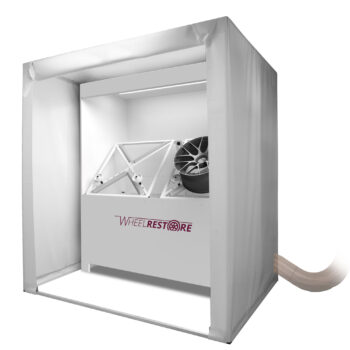

Aluminium Spraying Machine (ASM) is made to restore and repair larger damages on Diamond Cut Alloy Wheels, with a original finish, delivering a durable, OEM-safe repair in minutes.

The machine is not a welder—it’s an adaptive aluminium spraying system purpose-built for repairing diamond-cut alloy wheels. Just connect power, compressed air and the spray compound.